Set your business apart by weaponizing your support teams

Building a top-notch team is critical to the success of any company, and the best producers in the industry are adept at attracting high-caliber sales and operating personnel to manage day-to-day aspects of the business. These companies deliberately ensure that the people performing and supervising these functions are talented, committed, and well-trained.

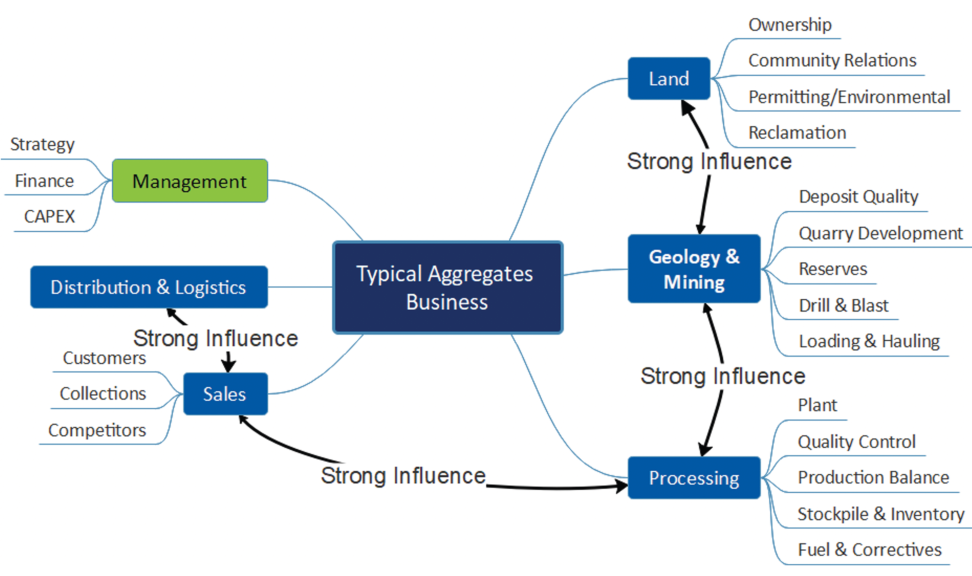

But the construction materials industry is complex, requiring attention to disparate factors that influence not only the day-to-day results but also the long-term performance of the business. So how can companies optimally manage critical long-term functions like environmental, geology, mine planning, and engineering? The right approach can determine if your business will thrive in both good times and bad.

Some construction materials companies choose not to actively manage these longer-term aspects of the business. The results are often inferior performance, legal peril, and even catastrophic events that take a toll on employees, the community, and the reputation of both the business and industry. Clearly not the way to run a responsible, profitable business. Fortunately, most companies choose one of three alternative approaches, with some yielding better results than others.

#1: Operations Carries All of the Load

Many businesses place the burden for mine planning, environmental compliance, and plant optimization on overworked operations managers. But a mine manager’s job is a full-time gig, and it is typically focused on short-term production and financial goals that can be in direct conflict with longer-term performance and sustainability.

In many cases, these short-term objectives drive short-term thinking, resulting in high-graded deposits, sterilized reserves, permitting fire drills, improperly located infrastructure, and shortened mine life. Unfortunately, even highly competent managers with substantial experience can fall into these traps, and the consequences are expensive, often far more so than full-time staffing of long-term functions.

#2: Specialized Support Functions

Many successful businesses invest in teams of specialists to manage these ancillary but necessary activities, which is a far better option than overloading the site manager or doing nothing at all. This approach improves recovery of reserves, maintains environmental compliance, and frees the operations manager to focus on efficient production.

The tradeoff of course is incremental costs, with businesses taking this approach carrying more internal staff or managing external specialists. History has shown these incremental costs pay for themselves many times over in operating efficiencies and reserves optimization.

Unfortunately, many businesses view these additional costs as profit-sucking overhead. This often manifests as reluctance to provide ample resources, with support teams typically among the first to be cut when a downturn comes. This approach will inevitably have erratic results and will usually leave opportunity on the table.

#3: Weaponized Support

The most successful construction materials businesses take things a step further and use support teams to establish a competitive advantage. This means the support functions are all actively trying to improve the business within their sphere of influence rather than simply ticking the boxes. Examples of this are:

- Close coordination between geological, mine planning, engineering, and environmental support to ensure permits are compatible with profitable operations (e.g., the right areas are permitted, mining sequences make sense, operating hours are sufficient, etc.).

- Understanding site geology and using that information to predict quality and yield over time, and to plan accordingly.

- Taking deliberate, measured steps to engineer entire mining and production processes to match business needs with the geology or situation at the site. This can minimize costs, leading to superior performance and greater flexibility.

- Managing to an overall site plan, with permitting, operations, and reclamation performed in a way that yields significant value during the production and post-mining phases.

The best part of this approach is that it delivers value without being much more expensive than Option #2, but it does require management attention and support. We have seen companies that use this approach be wildly successful during high points in the cycle, then thrive and expand during low points.

Of course, there are different approaches to building these elite teams. Having internal experts is a viable choice for medium and large businesses with economies of scale, and when there are regular or day-to-day duties to perform, e.g., safety, QC, or logistics. External experts and hired guns are a good fit for businesses that lack internal staff and for situations for which duties are hyper-specialized or are needed only periodically.

Building up, tearing down, then building up support structures again should not be part of the recipe, nor should arbitrarily shuffling responsibilities during a downturn. A strategy of employing active, engaged support teams, whether internal or external, is difficult to execute and requires consistent support from management, but the long-term rewards are worth it.

About the author:

Erik Warm is senior consultant for Inlet Capital Group. A professional geologist, he has more than 20 years of experience in the aggregates industry. He can be reached at ewarm@inletcapitalgroup.com or 561-529-5569.

Erik Warm is senior consultant for Inlet Capital Group. A professional geologist, he has more than 20 years of experience in the aggregates industry. He can be reached at ewarm@inletcapitalgroup.com or 561-529-5569.