Intelligent dredging

Not long ago, plant automation was a novelty, a technology of the future with a price tag to match. Today plant automation is ubiquitous and cost effective, with sites staffed by skeleton crews and run by remote operators. Until recently, this level of automation was limited to higher value commodities like metals, frac sand, and the like, but producers of construction aggregates are increasingly seeing the economic benefits of increased automation.

Today’s tight labor market has made skilled equipment operators hard to find, while rising energy costs have pressured operators to reduce diesel consumption. In this environment, sand and gravel operators are looking to dredging systems as a possible solution. A single dredge can replace an excavator, loader, pit dewatering equipment, and multiple dump trucks. And as dredge manufacturers have begun offering varying levels of automation in their systems, there is a reliable and cost-effective dredging solution available for almost any operation.

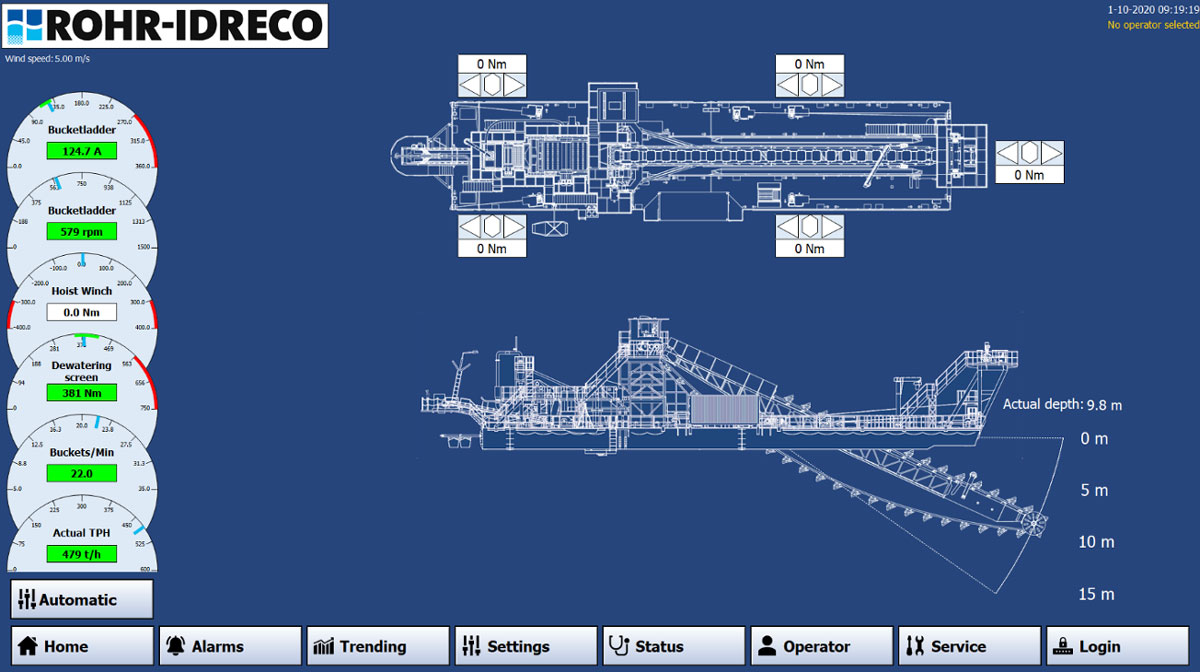

The idea of intelligent dredging began almost a decade ago, with the movement toward electric dredges. Initially, intelligent dredges were designed with an “Auto Mode” in which sensors could control pump speed, suction placement, and relief valve action on suction dredges, and telemetry systems could control bucket cycles on clamshell dredges. Today, a wide variety of readily available sensors can push intelligent dredge capabilities to an entirely new level.

-

- Auto Mode – This mode controls the excavation process, while the operator sets preset value ranges for vacuum, line velocity, discharge pressure, and density readings. The control system receives feedback from the associated sensors and makes operating adjustments in real time. The dredge operator monitors and moves the machine while the system operates itself.

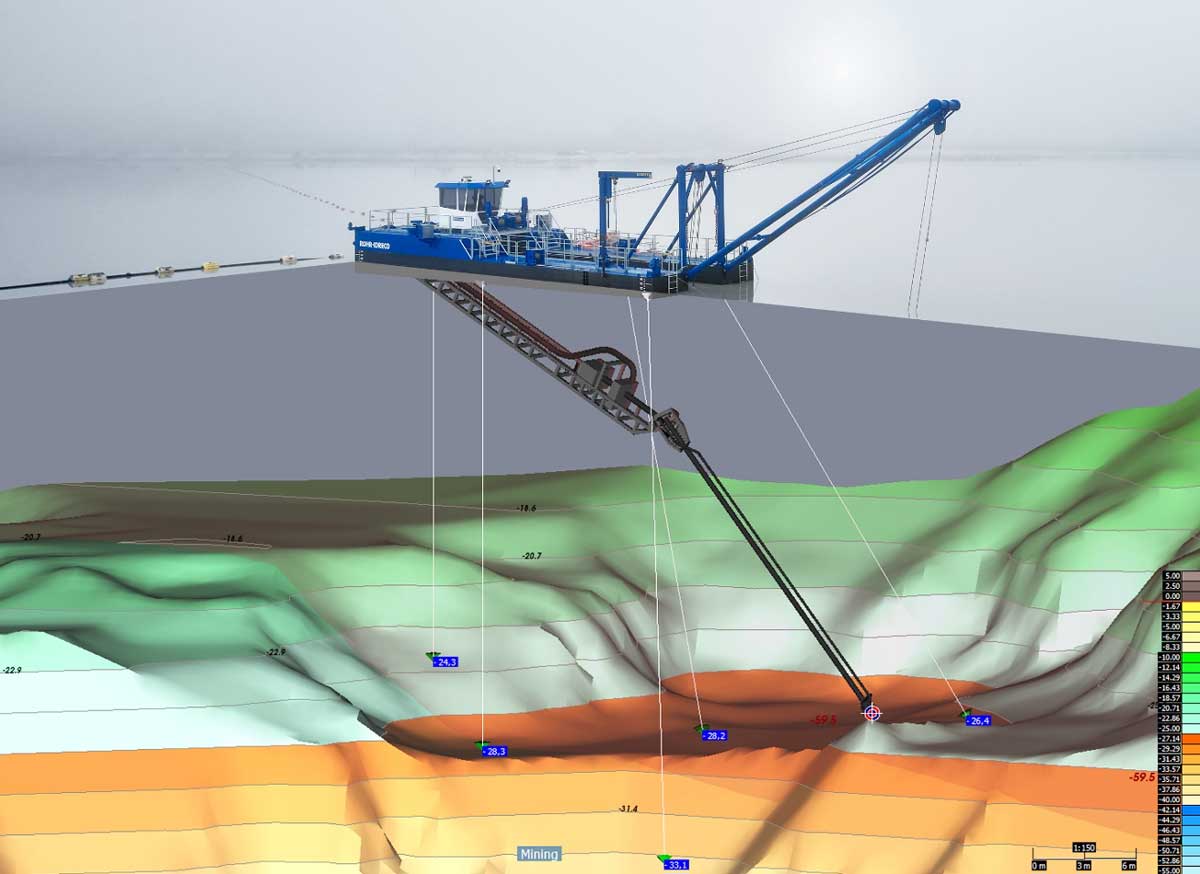

- Visualization – Dredging has historically been a blind operating process, but today’s dredge systems create live maps of underwater surfaces, allowing the operator to visualize sluffing walls, post holes, and bank slopes. The systems allow the operator to mark these key details, thereby minimizing operational issues and dramatically improving reserve recovery.

- Remote Access – Utilizing cellular and/or wi-fi connections, dredge manufacturers can connect directly to the system to access performance information, trouble shoot, and provide technical support.

- Remote Operation – With a few additional sensors and a robust internet connection, some systems can be operated from the scale house. Although remote operation requires a stable connection, most often via fiber optic cable, there are dredge systems currently operating with no one on board.

- Complete Automation – By integrating the operating system with the sonar system, adding sensors for positioning, and introducing some special programming, a fully-automated dredge becomes reality.

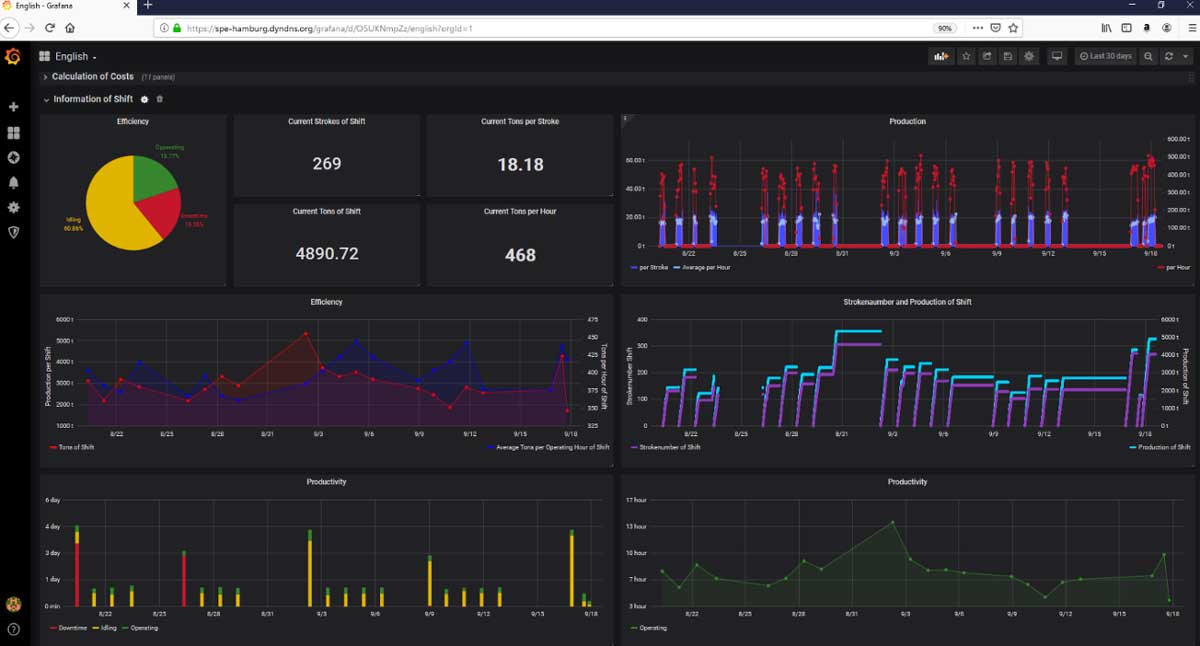

- Preventative Maintenance – Using the dredge’s robust data compilation capabilities, dredges monitor tons, hours, amps, and other operating metrics used in preventative maintenance programs. The system can report this to the owner and manufacturer, enabling improved maintenance scheduling and ordering of long lead-time parts.

Intelligent Dredging does more than simply replace multiple machines with a single unit; it moves the excavation process in the same direction as the plant process—reducing cost, raising efficiency, increasing reserve recovery, improving operator conditions, and optimizing the entire system from excavation to plant feed. In a world of tight labor and high energy costs, intelligent dredging is a solution worth exploring.

About the author:

Richard Crowe is senior consultant for Inlet Capital Group and head of Rohr-Idreco Americas. He has nearly 20 years of experience in plant and area level operations management. He can be reached by email at rcrowe@rohr-idreco.com or 936-446-9976.

Richard Crowe is senior consultant for Inlet Capital Group and head of Rohr-Idreco Americas. He has nearly 20 years of experience in plant and area level operations management. He can be reached by email at rcrowe@rohr-idreco.com or 936-446-9976.