Green Producers: Time

This article is the fourth of a five-part series on green producers, and why we should celebrate those who have been doing it well and will continue to do so.

In this series comparing green producers and great producers, we have thus far addressed reserve recovery, end-of-life land use, and water management. But these producers have so much more in common, including their optimization of the invaluable resource that is time. Downtime, maintenance time, service interval time, operating time, tons per man-hour….few resources are as measured and managed as time. No wonder that both green producers and great producers strive to make each hour as valuable as possible.

Every shift has a fixed number of annual hours. How those hours are utilized, be it for sales, operations, or maintenance, ultimately determines how well a site performs. Consider the concept of scheduled maintenance. The cost to fix something after it fails can be two, three, four times that of a scheduled repair. But breakdowns like this also have an impact on time, demanding the immediate attention of the maintenance crew while decreasing the productivity of the operating crew. Once repairs are complete, these crews must often work additional hours to make up for the time lost to unscheduled maintenance, which increases cost to the company and burden on the workforce.

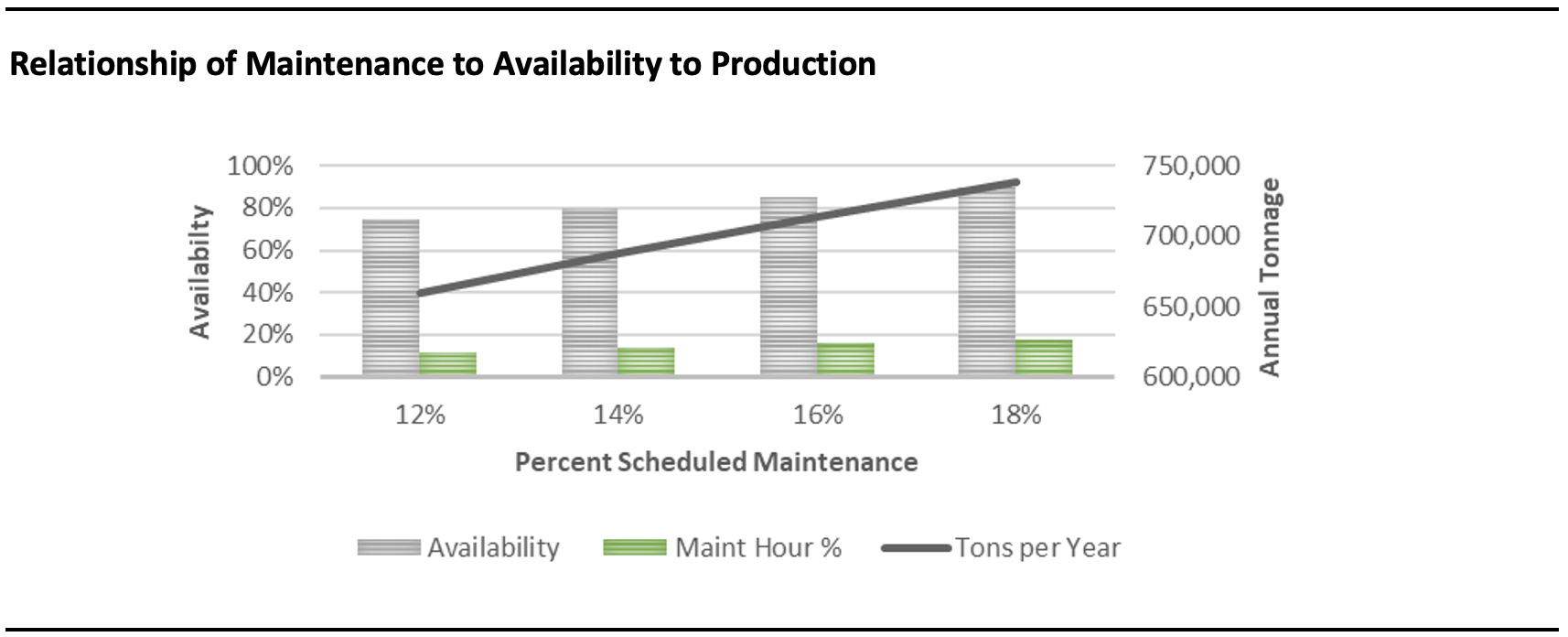

Creating the proper balance between scheduled maintenance time and scheduled operating time minimizes breakdowns. This in turn reduces unplanned overtime as well as stress placed on the workforce, providing a healthier and more efficient work environment overall. Empirical data reveals the merits of this approach.

Why is this important? The effects of increased preventative maintenance on availability and production are well-established. The great operator embraces this, recognizing that increased profits are there for the taking.

But preventative maintenance also has a meaningful effect on time, in that it reduces the number of production hours required to meet demand. With the economy booming and unemployment falling, it has never been more challenging to find qualified personnel. In this environment, most employees are simply not willing to put in 70+ hour weeks. They value their time, and they expect their employers to do the same. The green operator understands this and leans into work-life balance.

The great operator is trying to maximize productivity and minimize costs, and he concludes that by installing a world-class preventative maintenance program or creating minor improvements in efficiency, he can increase tons per man hour, thus extracting more value from each unit of time.

The green operator, in accommodating work-life balance concerns that emerge in a tight labor market, looks for opportunities to reduce the burden on his people to improve their overall job satisfaction. The two operators arrive at the same solution…better maintenance that makes everything and everyone more efficient. In the end, the company enjoys more profit, and the employees are happier and more engaged.

In the final article of the series, we will explore how green operators and great operators consider power, something high on every list of green improvements. Tackling this topic should be easy, right?

About the author:

Richard Crowe is senior consultant for Inlet Capital Group. He has nearly 20 years of experience in plant and area level operations management. He can be reached at rcrowe@inletcapitalgroup.com or 561-529-5569.

Richard Crowe is senior consultant for Inlet Capital Group. He has nearly 20 years of experience in plant and area level operations management. He can be reached at rcrowe@inletcapitalgroup.com or 561-529-5569.